Hydraulic motors

What is a hydraulic motor?

hydraulic motors are rotating equipment that play a key role in various industries. A hydraulic motor is needed in all machines that require rotary motion. Industries such as automobile manufacturing, cement-related industries, chemical industries, mining industries, etc. are some of the cases in which hydraulic motors are used. The construction of hydraulic motors is very similar to hydraulic pumps, but the process that occurs in hydraulic motors is different from pumps. The energy contained in the pressurized hydraulic oil is received by the hydraulic motor and converted into torque and rotational movement; In other words, hydraulic motors apply the reverse action of the hydraulic pump on the fluid (hydraulic oil).

Types of hydraulic motor according to the type of operation

- Hydraulic motor with limited rotation

- Hydraulic motor with continuous rotation

Types of hydraulic motors

- gear hydraulic motors

- piston hydraulic motors

- vane hydraulic motors

-

Gear hydraulic motor

Gear hydraulic motor is similar to gear pumps in terms of internal construction, and the gears are internally or externally engaged with each other. The larger the gears, the higher the output torque, and as a result, the speed of the hydraulic motor will be lower; It should be noted that if the gears are small, the torque will be less and as a result the speed of the hydraulic motor will increase. The maximum speed value in geared hydraulic motors is 1000 rpm.

In today’s advanced world, the need for a hydraulic motor in the industry as a hydraulic operator is felt more than ever. Among these, geared hydraulic motors are the most widely used in the industry and are known in the industry as a device for creating rotational movement. As mentioned earlier, the reverse hydraulic motor performs the work of the pump. In this way, they receive hydraulic energy from the fluid and convert it into mechanical energy.

Geared hydraulic motors have many advantages. Some of these advantages are:

- The most important feature of these hydraulic motors is to have high efficiency.

- Gear hydraulic motor bearings have high strength against axial and radial forces.

- They have compact dimensions and They occupy less space than other hydraulic motors.

- These hydraulic motors have a higher speed than other hydraulic motors and have a smooth and quiet operation.

-

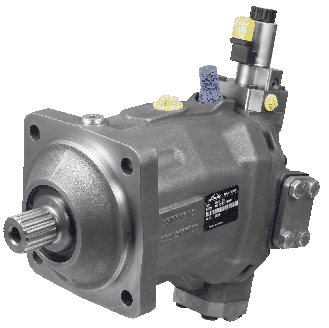

Piston hydraulic motor

The internal structure of this class of hydraulic motors is also very similar to piston pumps; In this way, a number of pistons are installed on the cylinder and these pistons, with the help of the pressure that the fluid exerts on them, lead to the rotation of the cylinder. Piston hydraulic motors have a compact structure and have high torque, high acceleration, and good service life.

-

Vane hydraulic motor

Vane motors are very similar in construction to vane pumps with a balance system. The internal structure of this group of hydraulic motors is designed in such a way that a set of pistons, which are usually odd in number, are installed on the output shaft and the body of the hydraulic motor. In this way, the torque leads to applying pressure on the end part of the pistons, which move back and forth, and finally this pressure will cause the rotation of the output shaft of the hydraulic motor. Basically, their output torque is created by applying pressure on the blades. As the rotor rotates, the vanes follow the surface of the cam ring. The sliding movement of the vanes on the surface of the cam ring seals the chamber and directs the fluid from the inlet to the outlet. Because there is no centrifugal force when the engine starts, spring force or fluid pressure is used to make contact between the vanes and the cam ring.

Advantages and disadvantages of hydraulic actuator system

Advantages:

Having high strength and power.

Disadvantages:

The best type has fluid (oil) leakage in terms of construction

Hydraulic oils are flammable

High cost to provide pump, tank, control and accessories

loud noises

High cost maintenance and repair and need a specialist

Need for scheduled service and check

The output of a motor is a torque and an angular speed (power = torque x angular speed)

Selection of hydraulic motor

To choose a hydraulic motor, at least the following must be specified:

– Oil displacement volume in cm3

– Maximum allowed flow through the engine and maximum speed

– The torque constant in Nm/bar can be used to calculate the torque value of the engine at different working pressures.

– Maximum engine torque in maximum pressure difference in Nm

The use of pressure control valves in the hydraulic motor circuit to protect against overload

In the figure above, you can see that when the flow is established from path A, the load pressure is, for example, 150 bar, and the flow exits from path B. Actuators or control valves do not do anything in this case and the hydraulic motor is working and rotating. until the pressure increases and reaches, for example, more than 200 bar. At this moment, one of the operators, which is in the form of the lower operator, acts and blocks the flow path from A to B. The excess load flow is removed from the actuator path until the excess load pressure is discharged and reaches zero.

Determining the necessary parameters of the hydraulic motor

In the continuation of the discussion, we mention some parameters and related formulas below:

Determining the rotational speed and flow rate of the hydraulic motor

N (rpm)= 1000 × Q (lit/min)/ Vg(cm3)

In this relation, N is the rotational speed of the hydraulic motor, Q is the required flow rate, and Vg is the displacement volume of the hydraulic motor.

Determine the power of the hydraulic motor

P (Kw) = T (N.m) x N (rpm)/(9550)

In this relation, P is the power of the hydraulic motor, T is the torque, and N is the rotational speed of the hydraulic motor. It should be noted that the above relationships are presented without considering the mechanical and volumetric efficiency. In practice, the efficiency values affect the actual torque and power consumption.