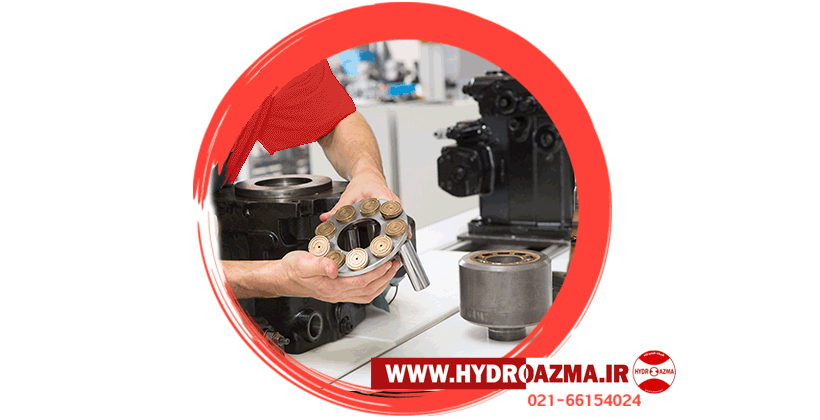

Repair of hydraulic pump, hydraulic motor and hydraulic valve

Hydroazma company is a specialized center for hydraulic repair in the field of hydraulic system equipment, including piston pumps, hydraulic motors, and solenoid valves from different brands, including:

Rexroth, Linde, Kawasaki, Komatsu, Denison, Parker, Brueninghaus, Caterpillar, Sauer Danfoss , Vickers (Vickers), Eaton , Liebherr and so on.

Equipment repair procedures

At the beginning of the hydraulic equipment entry into the workshop, a file will be created and a code is assigned to the equipment and it’ll be wash with the machine if needed. It is then transported to the test and adjustment unit if needed and if it’s needed to be repaired the equipment is taken to the relevant technical unit for initial troubleshooting.

After disassembly and thoroughly reviewing the components and initial troubleshooting, the Hydroazma experts will provide the customer with the relevant report to start the repair process if they so agree. After repair and troubleshooting, the hydraulic equipments are assembled and tested for correct performance and efficiency.

At the time of testing and adjustment we take photographs and videos of the test procedure and the related data will be recorded online. Upon completion, the hydraulic equipment will be packed and test report will be delivered to customer along with relevant charts including volumetric efficiency diagram at the pressures tested.

Services of Hydroazma Company

Hydroazma company is able to provide restoration and repair services of all kinds of hydraulic equipment with the help of its experienced experts, some of which are mentioned below:

- Types of piston, gear, vane pumps

- Types of hydraulic motors radial piston, axial piston, gear, vane

- Types of proportional valves, direction control, pressure control, flow control and cartridge valves

Features and equipments of HydroAzma Company include dynamic testing of hydraulic equipment, lathe, lapping machine, column drill, automatic washing device and more.

To contact the technical expert of professional solenoid valve and servo repair

In the following, examples of repairs and tests carried out by the experts of Hydroazma company will be given to familiarize with the repair and test method.

Denison hydraulic pump repair

Denison P30 model hydraulic pump made in America

Denison hydraulic pump after complete disassembly, its parts were first washed and then examined by Hydroazma experts, the defects are as follows.

- The weakness of the sealing of the port plate and the valve plate, which was solved with the lapping device of Hydroazma company.

- The wear and crushing of piston shoes (Piston Shoes) was fixed by the machine tool of Hydroazma company.

- Removing scratches and corrosion of the Swash Plate surface

- Checking the pressure plate springs and its health

- Check the regulator and service all its parts

- Complete assembly of the pump and its hydrostatic testing by the testing device of Hydroazma company to ensure the correct operation of the pump of the hydraulic device.

To communicate with a technical specialist for the repair of a gear or vane piston pump (cartridge)

Hydraulic motor repair

Repair report of STF radial piston hydraulic motor model STF400-6800-S72-F4B made in China

The hydromotor was disassembled and diagnosed by the experts of Hydroazma company. The steps to do the work are as follows.

- Polishing the sealing surface and checking the main shaft.

- Dismantling all pistons and testing the health of its shoes

- Checking and fixing the wear of piston cylinders

- Replacing the main shaft head and bottom bearings

- Inspection and replacement of hydromotor dividing valve seals and polishing of its surfaces

- Painting and performance test of hydromotor

- Then the hydraulic motor was tested by the test device and the accuracy of the hydraulic device was evaluated.

Parker f12 hydromotor repair

Eton hydraulic pump test

Repair of Rexrot hydraulic pump

What is overhaul or major repairs?

Overhaul is called complete and comprehensive restoration of industrial equipment. Overhaul is usually done in order to bring the desired equipment to favorable and acceptable conditions for the industry. Colloquially, overhaul is called testing and repairing industrial equipment at the installed location.

The overhaul process can be done for simple mechanical equipment such as a pump or an extensive production line in a power plant. In fact, all industrial parts need periodic overhaul. This process is usually done in the form of reconstruction, but for the parts that cannot be reconstructed, replacement is done.

Hydroazma company with more than five years of experience in the field of designing and fixing defects and renovating all kinds of industrial parts, by bringing together an expert and experienced team; It is ready to serve.

Hydroazma company provides the following services for factory overhaul, refinery overhaul, power plant overhaul, petrochemical overhaul and automotive industry equipment overhaul.

What is the price and cost of overhaul?

Usually, carrying out the overhaul process entails two types of costs for the organization:

- Direct costs of implementing the overhaul process

- Costs related to the equipment itself

Both costs fluctuate depending on the problem created, the amount of change, the type of parts, the time spent, and the expertise required. To save money, you can also implement this process with the right timing during the life cycle of the parts to avoid the overall costs of major repairs.

Due to the variable conditions for the overhaul process, it is not possible to set a specific price in advance, but you can contact our consultants in this profession to check the limits of overhaul and get information about the cost of overhaul and overhaul.

Professional valve repair

Hydroazma Company is a specialized center in the field of designing and fixing defects and renovating all types of professional valves, by bringing together an expert and experienced team; It is ready to serve.

Hydroazma Company offers the following services to its customers:

Repair and reconstruction of all types of electronic boards

Designing all kinds of LVDT boards

Calibration of all types of proportional valves based on Data Sheet and working conditions

Design and manufacture of valve parts

Testing according to the functional conditions of valves and issuing certificates

Replacement of consumable parts

Also, you can click here for more information and familiarization with professional valves.

This image has an empty alt attribute; Its file name is Proportional-valve-repair.jpg