Hydraulic pump test, hydraulic motor and hydraulic solenoid valve

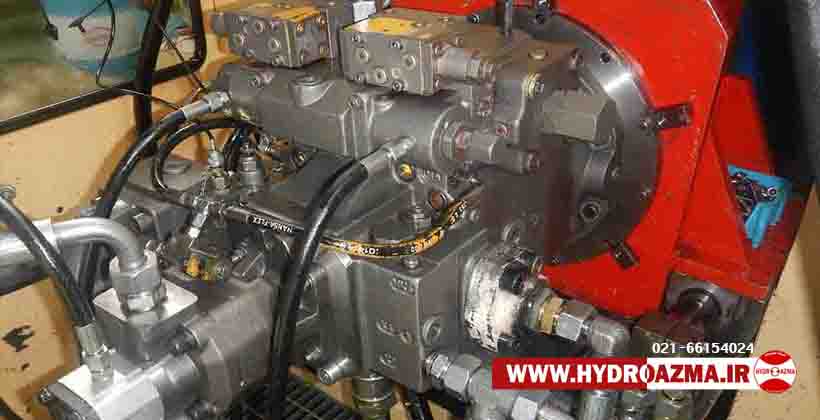

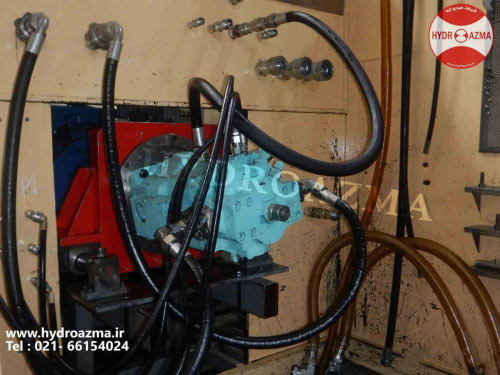

Hydroazma company is a specialized center for hydraulic testing in the field of hydraulic system equipment, including piston pumps, hydraulic motors, and solenoid valves from different brands, including:

Rexroth, Linde, Kawasaki, Komatsu, Denison, Parker, Brueninghaus, Caterpillar, Sauer Danfoss , Vickers (Vickers), Eaton , Liebherr and so on.

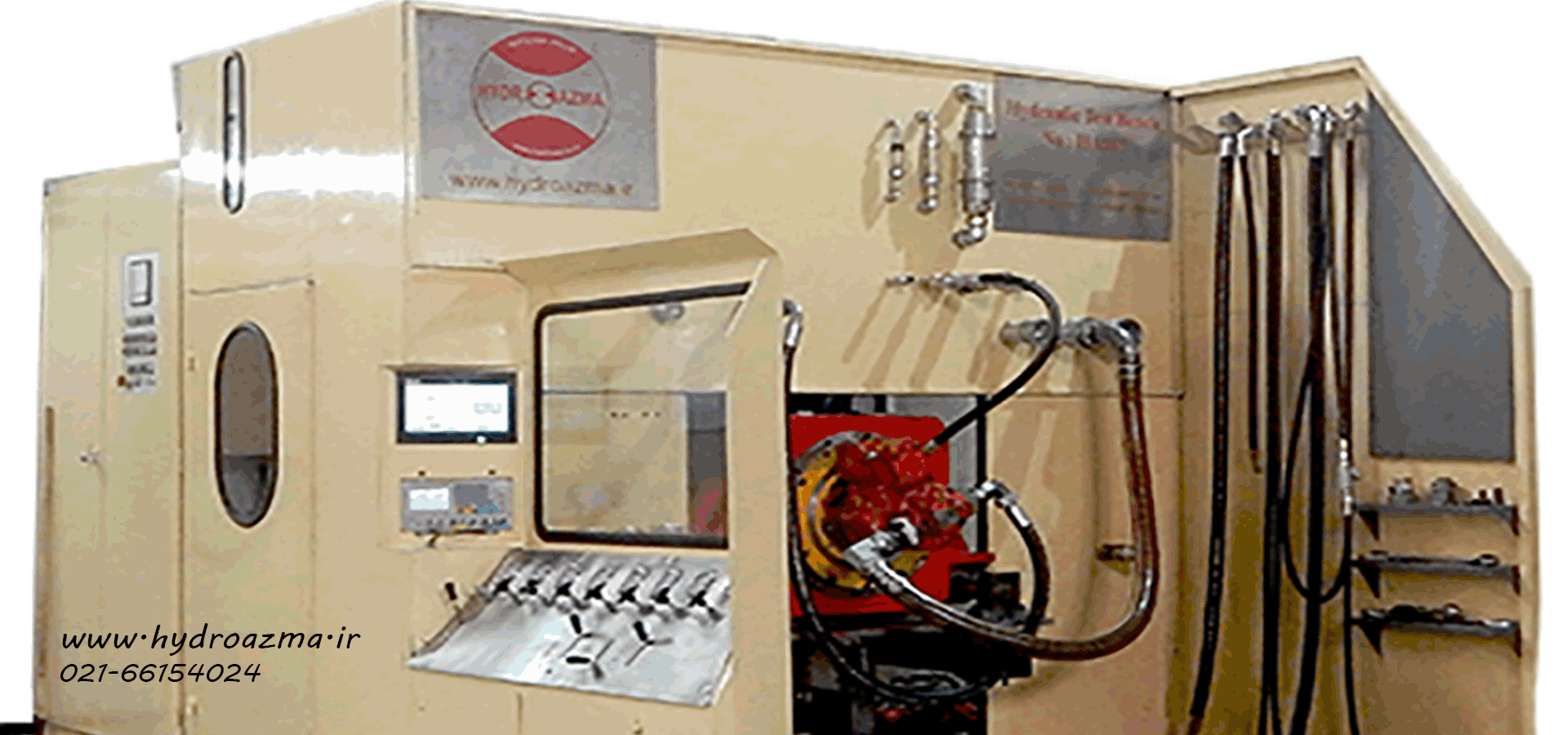

Features and equipments of Hydro Azma Company include dynamic testing of hydraulic equipment, lathe, lapping machine, column drill, automatic washing device and more.

Before working in real-life conditions, Hydraulic equipment should be tested under the simulated work conditions to ensure that they are properly functioning. Firstly, the creation of different working conditions at the workplace is not always possible; secondly, opening and closing the connections in the real working environment is a hard and time consuming task.

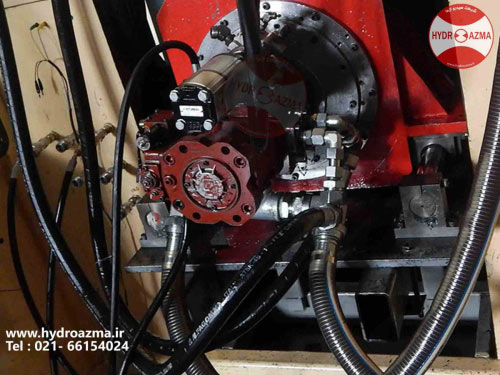

HydroAzma test bench allow you to simulate the actual work conditions for hydraulic equipment such as pumps, hydraulic motors and hydraulic valves. HydroAzma testing devices have the ability to apply and control the flow, pressure, torque and velocity dynamically in the equipment, as well as the temperature, leakage, ability to calculate the pump volumetric flow, and other required graphs.

To contact the technical specialist of professional solenoid valve and servo testing

Services of HydroAzma Company

HydroAzma has the aim of customer satisfaction and it has always tried to keep the customer informed of all steps involved. In this regard, the following actions are always taken:

1- Recording test data to report along with required charts

2- Adjusting the settings as requested by the customer

3- Imaging and filming of testing and adjustment of equipment for presentation to the customer

Why test hydraulic equipment?

After repairing a hydraulic equipment and installing it on the mother machine, the machine may not function properly. In this case, if the repaired equipment has a problem, it should be reopened and sent for repairs at a cost and waste of time, or if the machine has a problem. Another because the performance of the equipment or repaired equipment is not guaranteed, there may be a problem in diagnosing the defect and the repaired equipment will be reopened and sent to be repaired!

In the dynamic test of hydraulic equipment, including pumps, hydraulic motors and hydraulic valves, etc., their performance is simulated with working conditions, and the reference is to ensure the correct operation or defective equipment.

To communicate with a technical specialist for gear or vane piston pump testing (cartridge)

Advantages of testing hydraulic equipment in Hydroazma Company

- Avoiding spending time and money: If you do not test and install on the relevant machines and do not perform the expected performance, you need to re-open and close the equipment (loss of time and cost) and repair and troubleshoot it again.

- Ensuring the correct operation of hydraulic system equipment

- Helping to troubleshoot the hydraulic system

- Adjustment according to the hydraulic circuit of the manufacturer during equipment testing

- Determining the volumetric efficiency and how the hydraulic equipment works

Tests done by hydroazma

Hydraulic test

Hydraulic test Denison hydraulic pump test

Denison hydraulic pump test Denison hydraulic pump test

Denison hydraulic pump test Rexroth A10V pump

Rexroth A10V pump Vickers pump test

Vickers pump test Rexroth pump test</div >

Rexroth pump test</div > ALLWEILER hydraulic pump test

ALLWEILER hydraulic pump test Excavator pump test

Excavator pump test Eaton pump test

Eaton pump test Parker hydromotor test

Parker hydromotor test Hydraulic test

Hydraulic test Rexroth Pump test

Rexroth Pump test Komatsu pump test

Komatsu pump test stf piston hydromotor

stf piston hydromotor Denison pump test

Denison pump test Denison pump test</span >

Denison pump test</span > Kawasaki hydraulic pump test

Kawasaki hydraulic pump test Rexroth hydraulic pump test

Rexroth hydraulic pump test Rexroth A4CSG pump test

Rexroth A4CSG pump test Rexroth A4VSO pump test

Rexroth A4VSO pump test Rexroth A4VG pump test

Rexroth A4VG pump test Daikin hydraulic pump test

Daikin hydraulic pump test Hydraulic test

Hydraulic testAn appropriate test causes

- The amount of leakage of the hydraulic system is known at various pressures so that we can try to solve it. Therefore, by minimizing leaks, the desired equipment efficiency can be optimized. To be aware of the hydraulic system leakage and solving it can prevent serious damage and higher repairing costs and oil losses.

- In case of any problems which can lead to an increase in the temperature of the system, the testing can show the overheating, then we can solve the problem.

- Proper operation of the safety valves and safety systems in the equipment under high operating pressures is to be reviewed, as the failure of function of these systems can result in fundamental and irreversible damage.

- Proper operation of the flow control and pressure control valves in pumps and other hydraulic equipment can be tested and adjusted according to the map provided by the manufacturer.

By such possibilities that can lead to identify possible defects, the hydraulic system can be set up so that beside proper and secure function, the components of the hydraulic system have a useful lifetime. Therefore, the need for a system that provides these conditions is important.

HydroAzma Company, with the combination of theoretical knowledge and technical experience, has done this with the use of expert manpower and special testing equipment. The test facilities of HydroAzma are:

- Dynamic testing of all types of hydraulic pumps including gear pumps, piston pumps, vane pumps, open loop and closed loop pumps.

- Dynamic testing of a variety of hydraulic motors including positive displacement motors, variable displacement, open loop and closed loop.

- Ability to create adjustable speeds up to 3000 rpm and various pressures up to 450 bar in hydraulic equipment and power up to 160 kw

- Adjustment of variant types of control valves for pumps including constant power system, LS, DRG and proportioanl valve for achieving the desired controls.

- Ability to test and calibrate proportional Valves