Familiarity with lubricants and industrial oils

Familiarity with lubricants and industrial oils

Lubricants are very important products and compounds without which the movement of machines and industry is not possible. Lubricants generally include more than 600 different types of products with different quality levels and different viscosities. Engine oil, gear oil, hydraulic oil, turbine oil, compressor oil and grease can be named among the most important and widely used lubricants. The science of lubrication and lubricants includes various sciences such as: chemistry, physics, materials and mechanics.

The science of lubrication and lubricants is one of the most important and widely used sciences in the world because people are always and everyday dependent on this science and its applications. Currently, this science does not exist comprehensively and in the form of university courses, and therefore the need to address it and explain its many applications is very important. In the following, while explaining the science of lubrication and introducing the types of lubricants, liquid lubricants that make up the major part of this industry.

What is lubricants?

Lubricants are substances that are used to reduce the amount of friction between moving and fixed surfaces, such as oils, greases, etc. In a simple definition, lubrication is a method to prevent friction and wear of moving surfaces that are placed on each other. What is expected from a lubricant is that, in addition to reducing friction and ease of movement of machine parts, it also has the ability to reduce energy consumption, protect parts from corrosion, wear and rust. In general, the most important tasks of a lubricant are: transmitting hydraulic power, preventing stress and impact, moving pollutants and sealing moving parts.

Types of lubricants

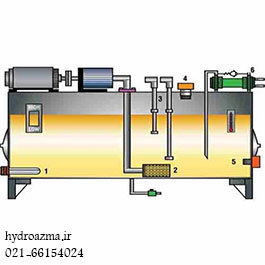

As you can see in the figure below, lubricants can be divided into two major categories: automotive lubricants and industrial lubricants. Industrial lubricants are also divided into three major categories of industrial oils, greases and other special lubricants such as metalworking lubricants, etc.

Of course, lubricants can also be classified according to the type of state. which are divided into four categories of gas lubricants, liquid lubricants, greases and solid lubricants.

Gas lubricants

Gas lubricants such as air, helium, liquid vapor, etc. are used in cases of very high or low temperatures, very high and low speeds, or in cases where there are nuclear radiations in the environment. One of the very important characteristics of gas lubricants is that their viscosity does not change much with temperature changes, and for this reason these lubricants can be used in a wide range of industrial applications. In addition, because gases are lighter than liquids and their weight can be ignored, this causes their flow to remain smooth and uniform at very high speeds. For this reason, they work better than liquid lubricants in very high speed bearings.

Gas lubricants have little friction, are free of impurities and do not have the property of overflowing that occurs in the case of liquid lubricants and greases. In addition, these types of lubricants can be safe materials in the food, pharmaceutical and chemical industries because they do not spill.

Lubrication of ultracentrifuges, precision grinding tool machines that work at high speed, dental drill wheel, atomic reactors, high-speed spinning machines, gas turbines, jet engines, etc. are among the applications of this category of lubricants.

Liquid lubricants

The most important liquid lubricants are oils, which are divided into two major categories: mineral oils and synthetic oils. These types of lubricants are the most common and widely used types of lubricants. Both categories are considered to be a kind of crude oil derivatives, with the difference that mineral oils are obtained from performing a series of separation operations on crude oil and at most one controlled chemical reaction, while more controlled chemical reactions are required to produce synthetic oils. and that is why the cost of synthetic oils will be higher than mineral oils. In general, mineral oils are produced more than synthetic oils due to their many uses in the production of lubricants. Of course, the capabilities of a synthetic oil are greater than those of a mineral-based oil due to the special reactions carried out on it, because perfectly suitable oils are artificially produced and cannot be discovered in nature.

Of course, apart from synthetic oils and oils whose main source is crude oil, there are other oils that are obtained from animals, fish and plants, which are called natural oils. The use of these oils as lubricants has been very common in the past, but nowadays crude oil is the main source of lubricants production. One of the characteristics of natural oils is their easy biological decomposition, which is superior to mineral and synthetic base oils in this respect. These oils cannot be stored for a long time, and they also have a high production cost. But due to the limited oil resources for energy production, natural oils can be a suitable alternative for oil derivatives in the field of lubricant production.

greases

Greases are among the most famous lubricants that are neither liquid nor solid. Greases are derived from a mineral or synthetic base oil and a hardener. In cases where lubrication with liquid lubricants is difficult and the possibility of re-lubrication is limited, these types of lubricants will be widely used.

Fully automatic grease injection machine

Grease distributor

Solid lubricants

These types of lubricants are used to work in special conditions such as vacuum, high load or high temperature and places such as nuclear reactors that are exposed to radioactive rays.

Being resistant in vacuum, low volatility, high temperatures and also against the energy caused by the radiation of radioactive materials is one of the most important properties of a lubricant, and solid lubricants have these properties.

Graphite, molybonium disulfide, bornitride, tungsten disulfide, and some solid organic compounds such as phthalocyanine and tetrafluoroethylene, mica, talc, etc. are among the types of solid lubricants, among which graphite and molybonium disulfide are the most widely used.

Leave a Reply