Design and manufacture hydraulic unit

Design and manufacture of hydraulic unit

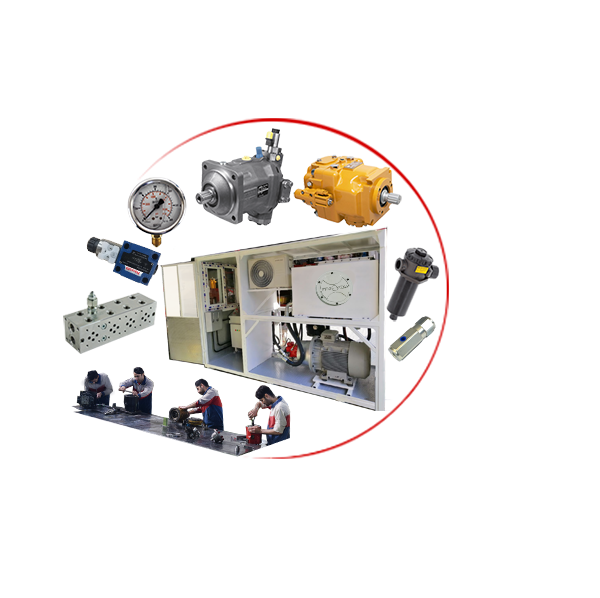

Hydraulic unit is a hydraulic unit that uses hydraulic fluid to move operators and actuators (hydraulic jack and hydraulic motor). This set includes hydraulic tank, electric motor (or combustion engine), hydraulic pump, pressure control valves, fluid flow and direction, and other installed tools and accessories.

How is a hydraulic unit made?

The manufacturer of the hydraulic unit must implement these items correctly. First, design the hydraulic unit. The design of the unit requires your knowledge of how the mechanical system works. So, first of all, the performance of the hydraulic unit must be determined and we must be fully aware of the efficiency of the hydraulic unit. Then simulate the hydraulic circuit by software to ensure the technical performance. After this, it is time to choose the components of the hydraulic unit. The selected parts for the unit must be prepared and assembled in the workshop. At the construction site, we start making metal parts and installing hydraulic parts on it. At the end of the work, we will test the construction of the unit from different directions so that the unit can be installed with full confidence.

To make a hydraulic unit, be fully aware of the operation of the industrial machine.

Making a hydraulic unit requires complete knowledge of everything in a mechanical system. So go to visit the location and conditions of the project and be aware of everything. Talk to the technical and executive officials and know all that is necessary for the design of the hydraulic unit. The environmental conditions and installation location of the hydraulic unit are very important for your design. Get full knowledge of the number of jacks, hydraulic motors and other hydraulic actuators. You need to know how many hours a day the system is going to work and how many operators are connected to it.

Knowing the conditions of a factory and the standards of that collection will help you to choose the quality of the parts correctly and indirectly know how serious they are to implement the project and how much budget they want to consider for this system. It is very important to visit a factory, as the technical experts of the Hydro-Azma Group do this for the construction of most hydraulic units and mention the obligations and construction conditions in person.

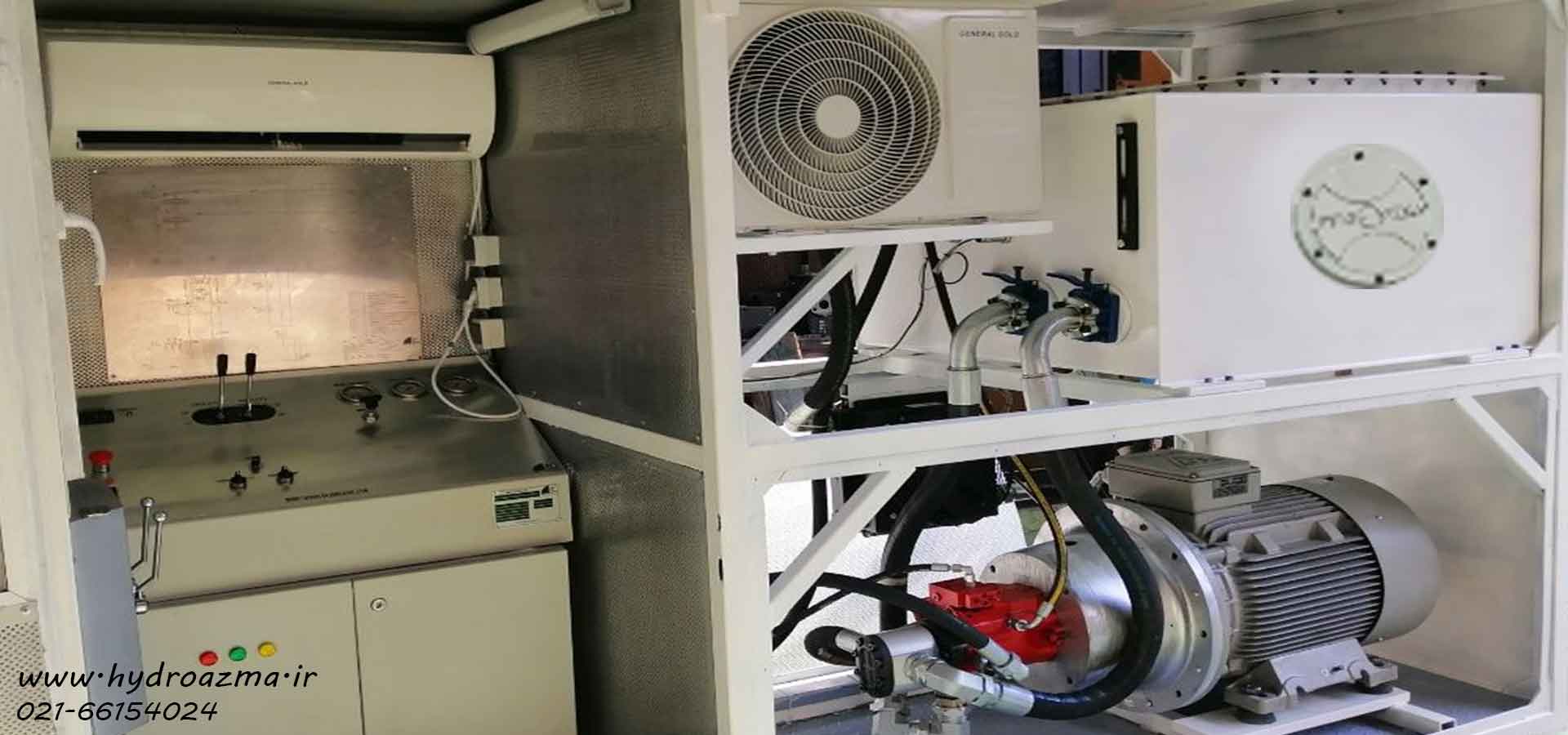

The simulation of the hydraulic circuit is very important for the construction of the hydraulic unit

Simple hydraulic systems with a small number of hydraulic elements are easy to implement and build. When the number of pumps and valves of a hydraulic system is large, but its circuit is not simulated, the possibility of error is high and it makes the construction of the unit difficult. Therefore, it should be implemented in one of the hydraulic simulator software to check the performance of the hydraulic system and circuit and prepare a comprehensive list of used parts. At the end of the project, the hydraulic circuit is delivered to the client to be stored in the archive of that collection to be used for repairs and other purposes. Hydroazma Group draws hydraulic circuit maps for all small, medium and large units and delivers them to the client.

Selection of hydraulic components and parts for the hydraulic unit under construction

The hydraulic circuit simulation provides you with a complete list of required parts. The selection of hydraulic unit components must be done very carefully in accordance with technical and engineering standards. Carefulness in choosing the main and original product is another important point that makes you maintain the high quality of your work and adhere to your obligations to the employer.

You need iron sheet for the hydraulic tank. Prepare the electric motor and hydraulic pump, as well as the equipment for connecting the pump to the electric motor according to the standard and system requirements. Hydraulic valves along with accessories and accessories such as steel block and… provide. Other accessories such as filtering system, cooling and heating, pressure and temperature sensors, dehumidifier, screws and connections should be available for you to consider their placement for the assembly.

Construction and assembly of hydraulic unit in hydraulic workshop

The construction of the hydraulic tank and assembly of hydraulic parts is done on the chassis of the unit inside the hydraulic workshop. In most units, the hydraulic tank plays the role of the chassis and all parts are installed on it. Therefore, the dimensions of the tank are very important and a plan should be drawn for it and the following steps should be taken:

The sheet of the hydraulic tank is bent and cut according to the plan and then carefully welded.

The lid of the hydraulic tank, on which the rest of the parts are placed, is thicker than the tank body.

The electric motor and hydraulic pump are fixed on the door through a pot. So a place for a pot is cut on the tank.

For the rest of the parts, such as valve manifold, filtering system, tank lid, fluid transfer hoses, etc., drilling and cutting must be done on the chassis.

After finishing the chassis and tank work, all parts are carefully installed and at the end of the work, the unit assembly is painted.

Testing the hydraulic unit after its construction and assembly

Hydraulic units are installed in important and sensitive parts of a factory, and the design and manufacturing team of the rest of the mechanical parts quickly connect the unit to the machine and start working. The manufacturer of the hydraulic unit must check the operation of the electric motor and hydraulic pump, the operation of the valves and sensors, the possible leakage in the tank and the connections after the construction and assembly, so that the least damage and damage is caused to the system during the installation of the hydraulic unit.

What are the steps of making a small hydraulic unit?

Small hydraulic units, which are also called mini hydraulic units, the most important feature of which is the small hydraulic tank. There are 10-50 liter oil tanks ready for hydroazma. The AC electric motor with a voltage of 220 volts (single phase or three phases) or DC with a voltage of 12 or 24 volts from 0.5kw to 3kw is coupled to a 0.5 liter to 9 liter gear hydraulic pump. There are one or two electric valves or manual valves along with a pressure relief valve on the mini unit. A suction filter, pressure gauge, tank lid, oil sight and hoses are other side parts of the small unit.

Hydroazma company is ready to provide service to you, dear customers, in line with the production of hydraulic units in the requested dimensions and specifications. Contact us for more information.

Leave a Reply