Basic concepts of hydraulics

Basic concepts of hydraulics and its application

Hydraulics is derived from the Greek word hydro. This word means the flow of fluid movements. In the past centuries, the meaning of hydraulics was only water, and of course, later the title of hydraulics took on a greater meaning, and its meaning and meaning was the study of more exploitation of water and moving water wheels and water engineering.

The concept of hydraulics in this century is no longer limited to water, but it has a wider scope and includes the rules and applications of other liquids, especially mineral oil, because water cannot be used as an energy carrier in industries due to its rusting property. be used and due to the fact that the oil does not rust, today it is widely used in industries, especially for energy transfer in the control system.

In short, it can be said: the technology that transfers and transforms power by liquids is called hydraulics. Since water hydraulics have the property of rusting, oil hydraulics are also used in industries for energy transfer in control systems.

Hydraulics is a branch of physics that deals with the mechanical properties of fluids and examines the uses of these properties in engineering sciences. Although only about 50 years have passed in the life of this science, it cannot be considered a new branch of science and in fact, Pascal, a French scientist in the 17th century, founded the basic principles and laws of this science.

The inability to produce washers and provide fully polished surfaces are perhaps the main reasons for the lack of development of this science before the 20th century. Due to the significant progress that has been made in the last few decades in the manufacturing of materials in the fields and methods of machining, the cases of using fluids in controlling various movements are increasing day by day.

The set of technical advances in the age of space and computer in recent years has dramatically changed the speed and efficiency of hydraulic systems, but the fundamentals governing all devices and various components are still the same. Hydraulic system works with water, oil or other fluids. In these systems, besides liquid, compressed air or some compressible gases and fluids can also be used.

A quick look at different fields of industry shows the wide application of hydraulics. For example, in agriculture, automobile industry, aviation industry, road and construction, chemical industry, defense industry, wood industry, marine industry, material handling, machining, mining, packaging, oil industry, printing industry, rubber industry, railway , textile, steel industry and even homes and public centers are used on a large scale and it is increasing day by day.

For example, in the aviation industry, the pilot controls the opening and closing of the wheels, vertical rudders, elevators and flaps with the help of hydraulics. In the pressure casting operation, hydraulic power is used to close the molds and inject the metal to make light parts of aluminum and magnesium. The body of the plane is also shaped with tension presses that work with hydraulic power.

Hydraulic applications

Hydraulics is the technology of production, control and transmission of power by fluid under pressure. In general, a hydraulic system performs four basic tasks:

- Converting mechanical energy into fluid power under pressure by means of pumps

- Fluid transfer to desired points by pipes and hoses

- Control of pressure, direction and fluid flow by valves

- Work done by operators

Basic concepts in hydraulics

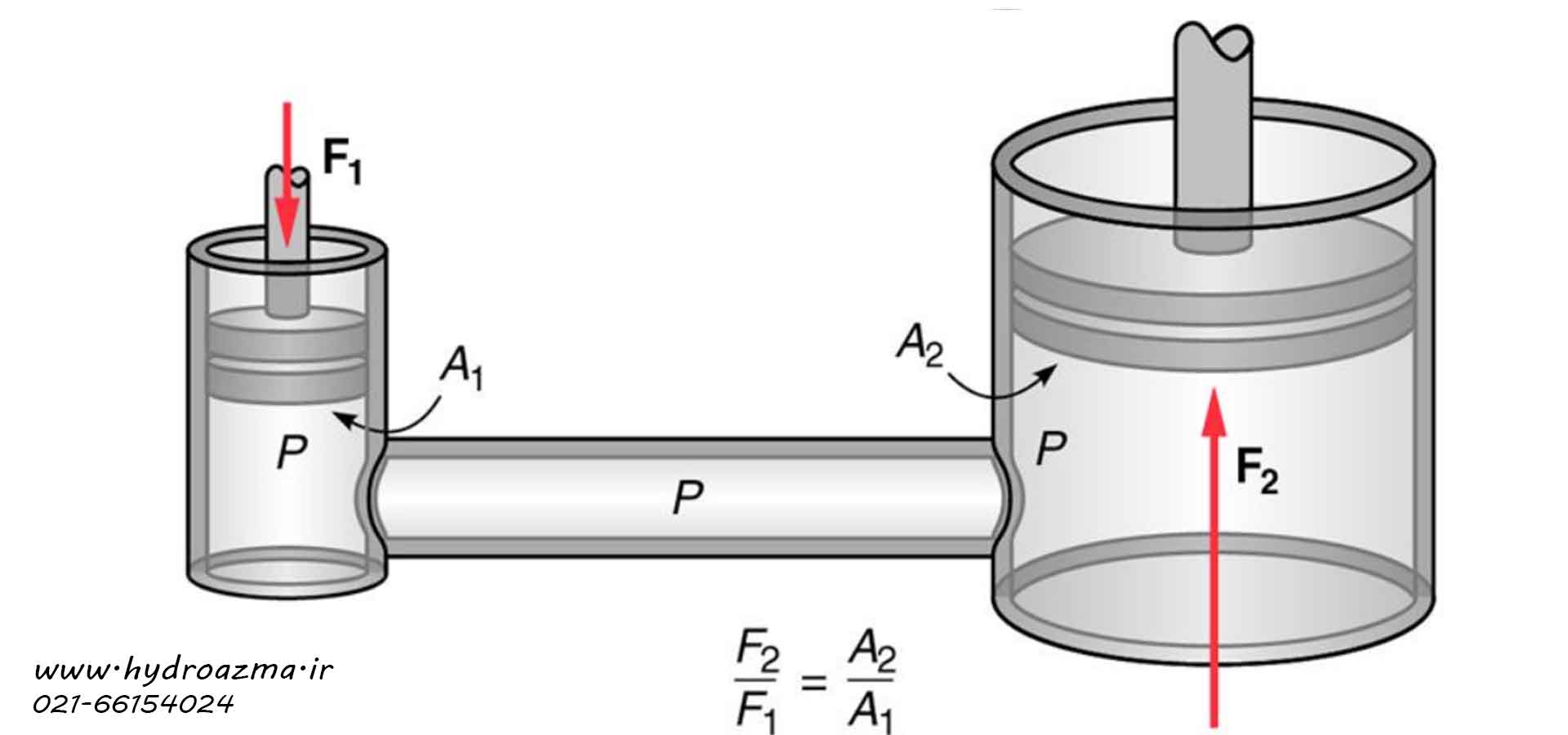

Pascal’s law

Pascal’s law is the basis of modern hydraulics. This law states that the pressure applied to any point of a confined fluid is transmitted equally in all directions and acts with equal force on equal surfaces.

Basic rules in hydraulics

Fluid under pressure always chooses the path with less resistance to pass.

The pump does not produce pressure but produces flow.

Pressure is created only against the resistance of an obstacle.

Although the above key principles seem simple, they are the foundation of hydraulic science. Having a correct understanding of these rules, it is easy to follow the movement of fluid in transmission lines and analyze the performance of the system.

Pressure

Pressure is the result of resistance to fluid motion. To calculate the pressure mathematically, the force is divided by the area. The unit of pressure is load. In practical hydraulics, one kilogram per square centimeter is usually equal to one load.

Determine the working pressure of the hydraulic system

To determine the pressure level in a hydraulic system, it should be kept in mind that by raising the pressure, smaller hydraulic elements can be used to reach the desired tonnage. Also, the diameter of the pipes can be chosen smaller, as a result, the cost of building the system is reduced. On the other hand, with an increase in pressure, the temperature of the oil in the system increases sooner, the leaks are more, and the friction and wear also increase, so the service interval should be shorter. Also, noise and pressure peaks are increased and desirable dynamic properties of the system are reduced.

actuator

The first task of an actuator unit is to create a desired movement or action for the robot so that the required force is expended to physically perform an action. There are three sources to create the energy of the actuator unit:

- Electric power

- hydraulic power

- Pneumatic force

Operators can be divided into five categories:

- Electromechanical actuators

- Electric machines such as AC motors, DC motors and stepper motors

- Piezoelectric actuators

- Micromotors

- Hydraulic and pneumatic actuators

Components of hydraulic systems

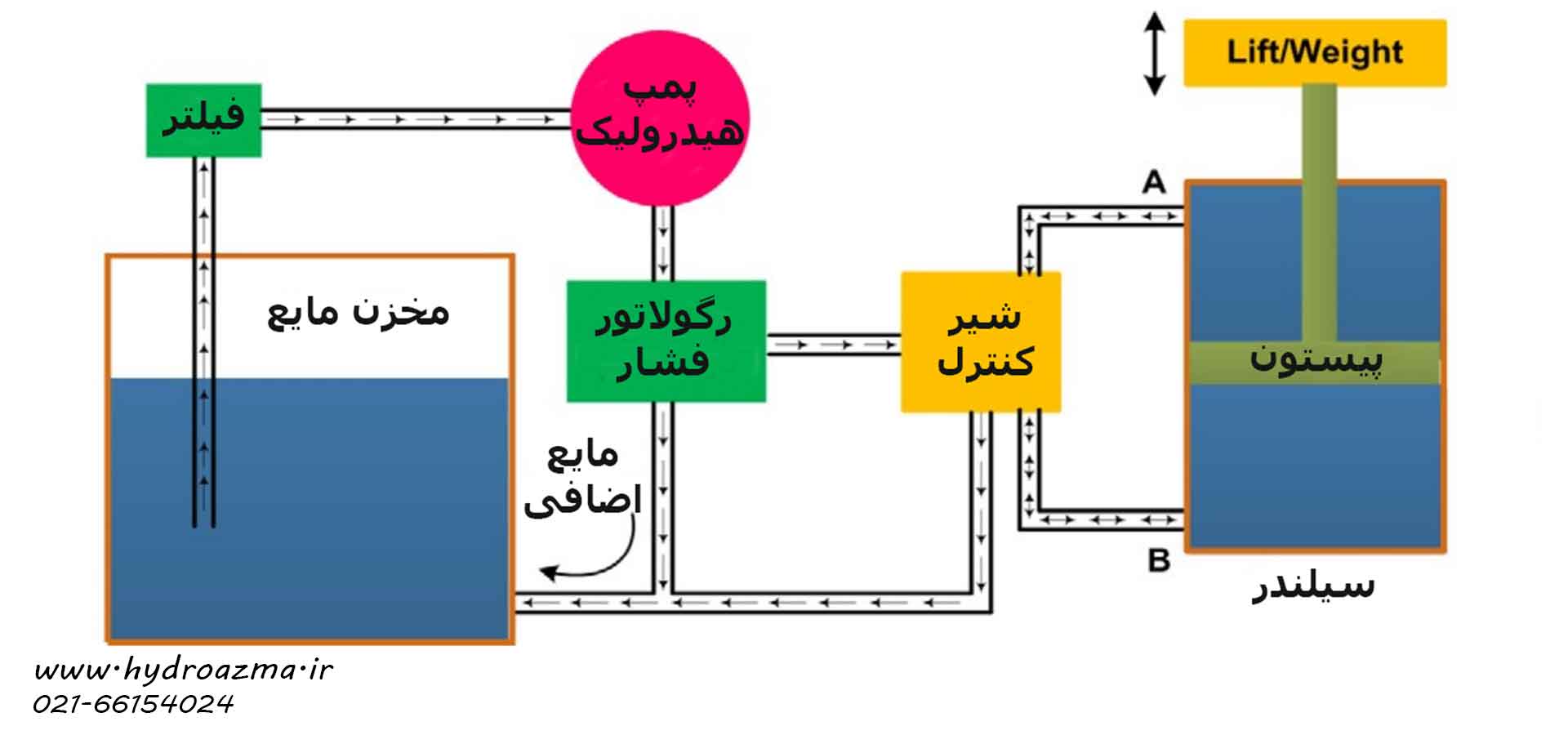

Hydraulics is the technology of generating, controlling and transmitting power by fluid under pressure. A hydraulic actuator system consists of the following components:

Hydraulic pumps: to flow fluid in the system

Hydraulic valves: to control the pressure, flow and direction of fluid movement

Accumulator (hydraulic reservoirs)

filteration

Oils and hydraulic oil tanks

hydraulic seals

Hydraulic fittings and hoses

Hydraulic motors

Hydraulic cylinders

The basis of a simple hydraulic system example

General problems of hydraulic systems

Lack of pressure, lack of flow

Pump howl, noise and vibrations

Excessive heat

Wrong movements of operators

Rapid depreciation of parts

Troubleshooting of hydraulic systems

Diagnosing means finding the problem of the system and must be clearly listed in a logical process to identify the defective part.

Troubleshooting steps

Review maintenance instructions

Check maintenance history

Conduct an initial visit

Reviewing and preparing a list of observed defects

Basic calculations

Determining the general factors of the problem

Determining the specific factors of the problem

Perform various tests

Leave a Reply